SPIDERNET

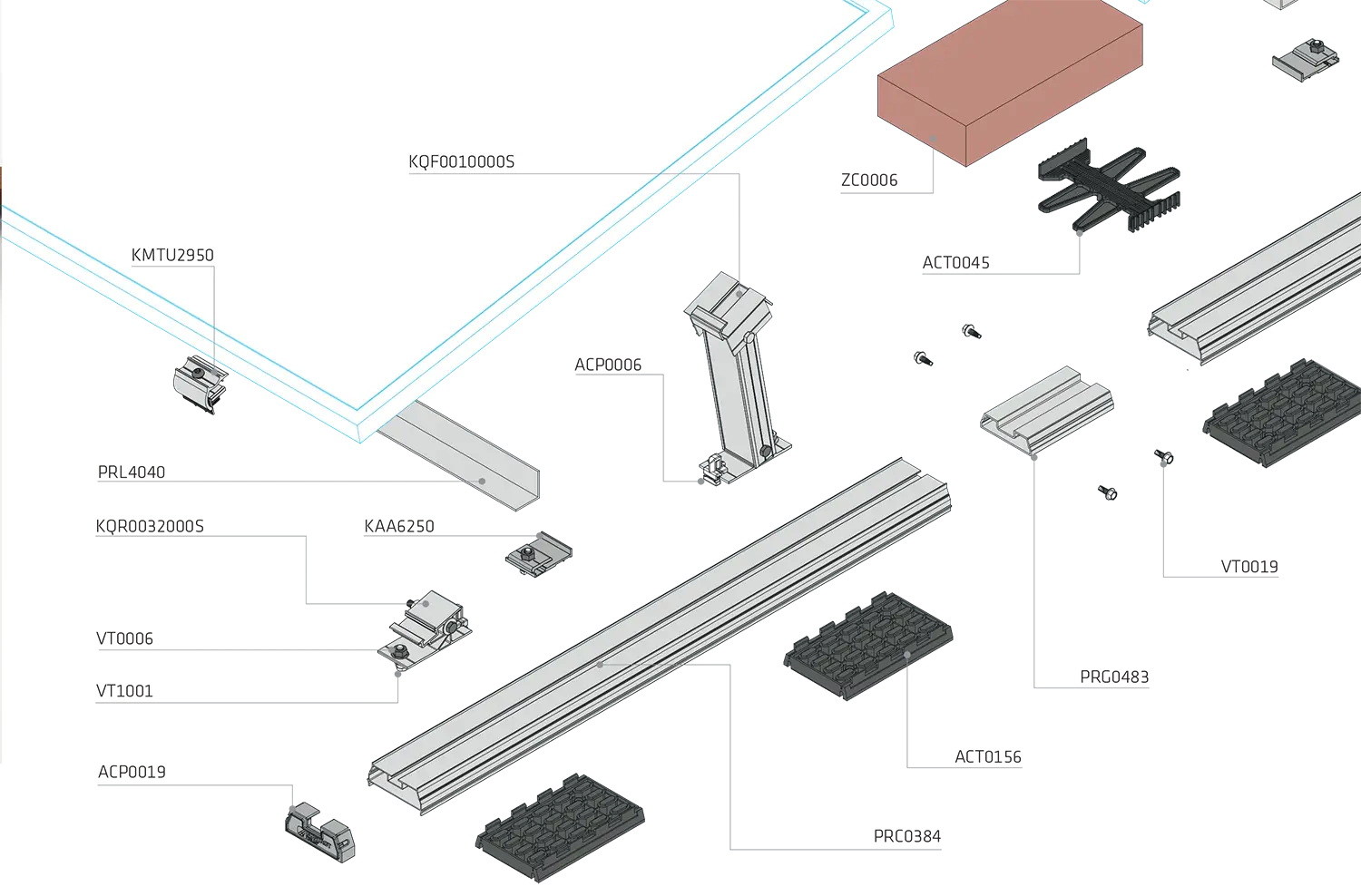

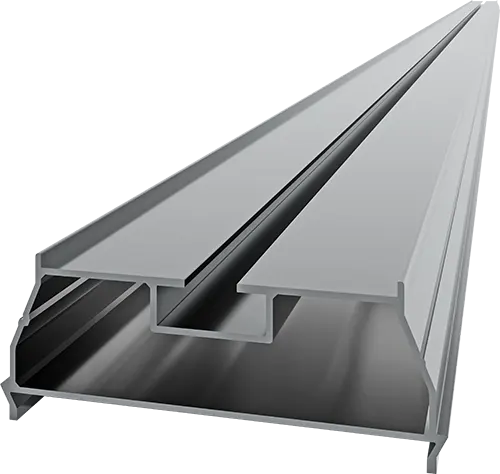

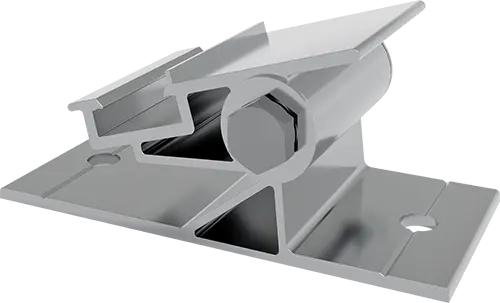

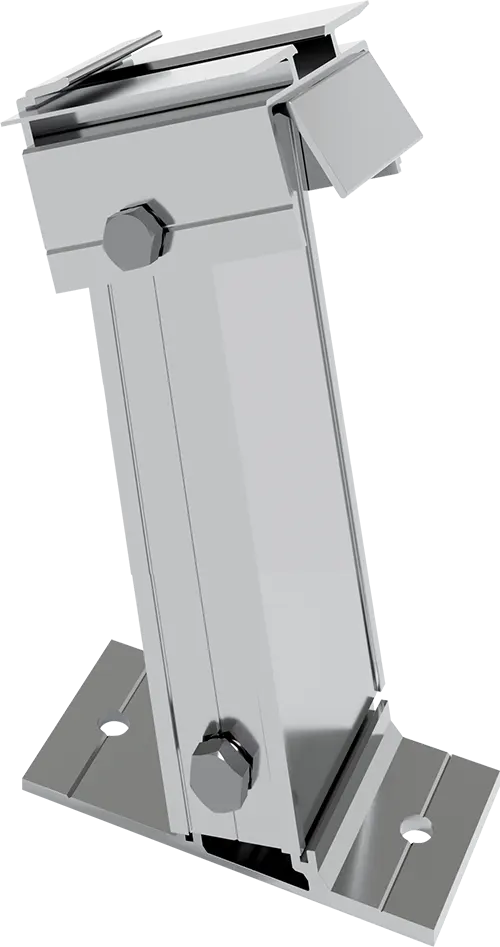

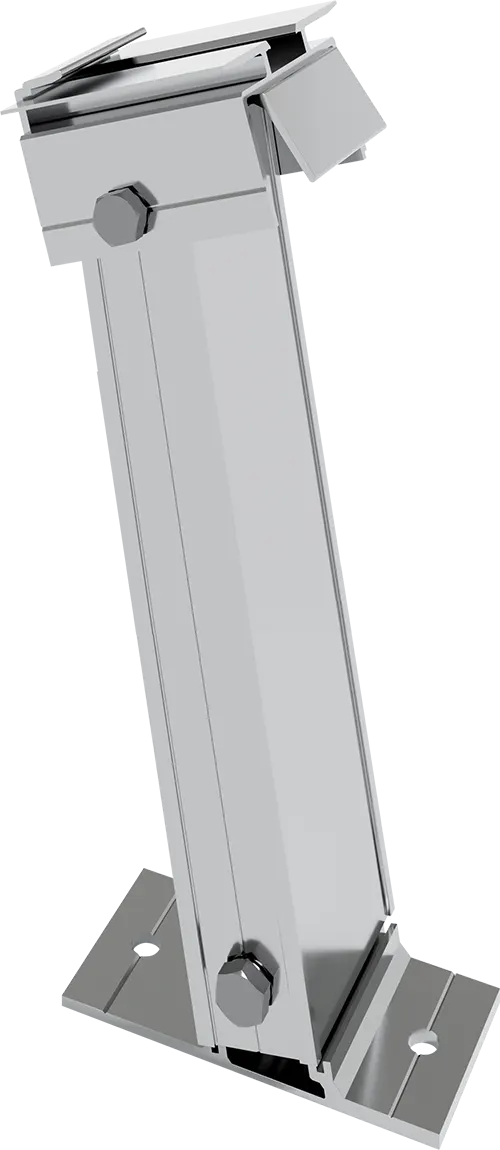

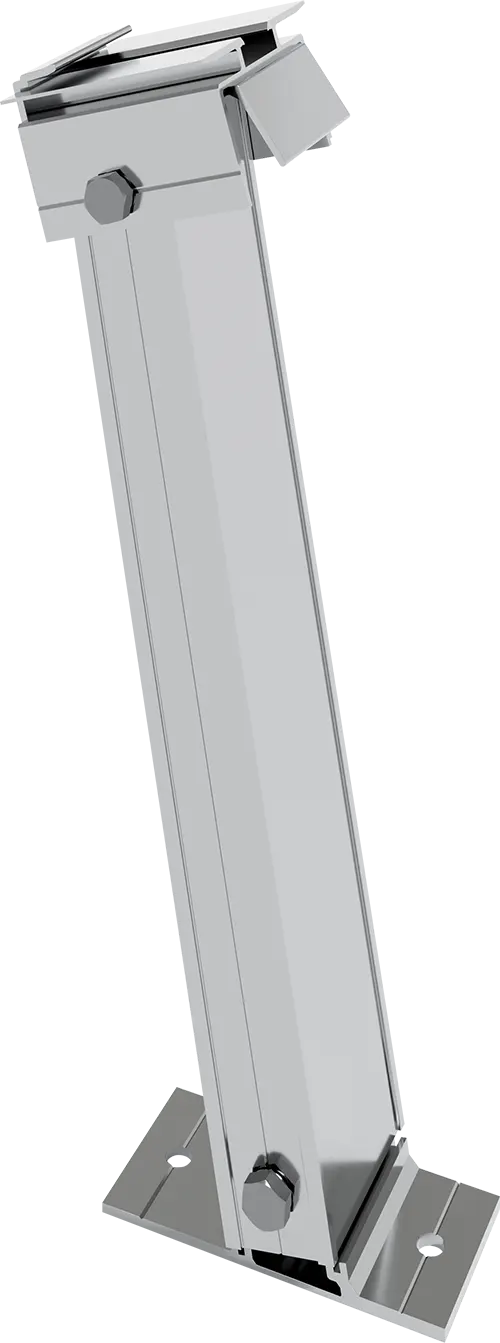

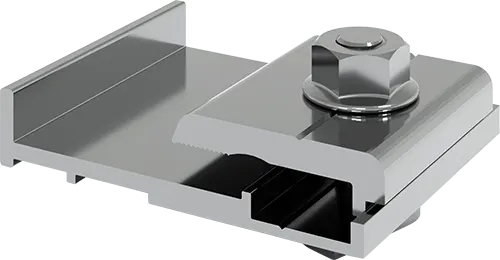

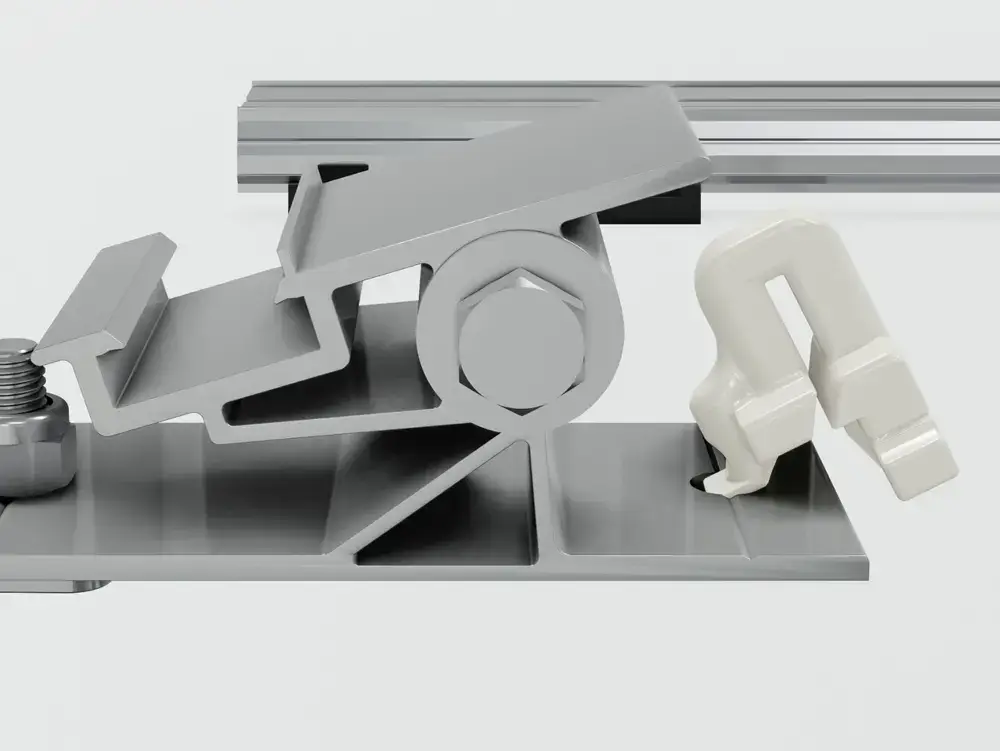

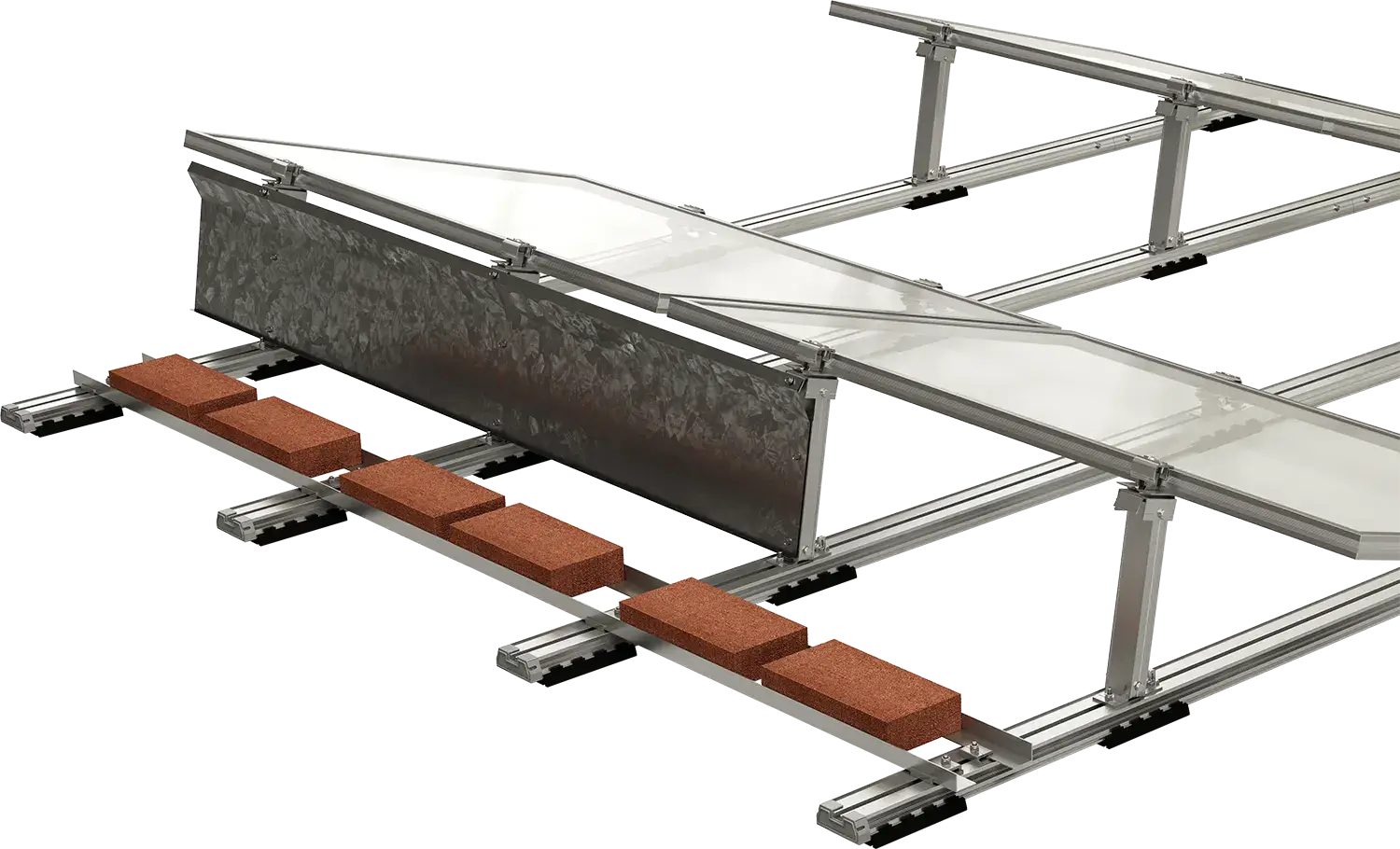

The system allows the chained assembly of rows of horizontally oriented panels. The system consists of a basic profile on which are mounted two support kits for fixing the panels.

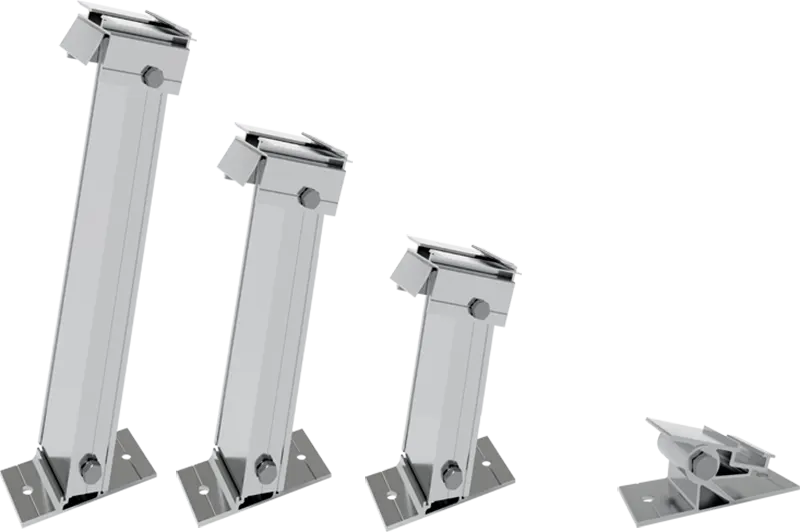

The front support kit has variable inclination, while the rear one has a fixed inclination.

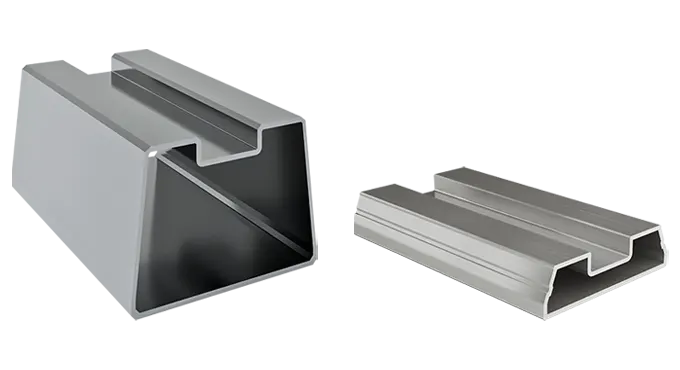

The rear kit is equipped with a protruding fins for fixing of the windbreak carter and an internal retainer for the panel frame flush mounting.